Tofflon CES system applied in VERO microsphere carrier 3D culture technology

- 2023-03-09

- News

- 900

I. Introduction

Vero cells are African green monkey kidney cells, which are isoploidy cells isolated and cultured from kidney epithelial cells of African green monkey.Vero cell lines are continuous aneuploidy cells that can go through many cycles of division without aging.

Compared to primary and diploid cells produced as vaccines, Vero cells have the following characteristics:

■Easy to source, fast growth rate, easy to culture, sensitive to a variety of virus infection, high virus proliferation titer;

■Stable genetic character, low degree of malignant transformation, can be used in the production of biological products;

■It can be used for large-scale culture through microcarrier and suspension culture.

Vero cells have been approved over the past two decades to produce many viral vaccines for human use, such as rabies, influenza, and polio.

2. VERO scale culture technology

The technology of large-scale culture of Vero cells after suspension domestication is limited in the production of biological drugs, and the technology is not mature.Therefore, in the actual production and application, the culture technology of Vero for the mass production of biological drugs generally adopts the microcarrier suspension culture mode. This culture mode integrates monolayer culture and suspension culture, which has the advantages of two methods and shows great advantages compared with the traditional culture mode:

●The microcarrier culture system has the highest surface area/volume ratio, which can provide enough surface area for cell adhesion growth in a small space, and the cell yield per unit volume of culture is greatly high.Compared with two-dimensional culture, it is not limited by surface area, which makes it possible to obtain higher cell density;

●After chemical modification, the microcarrier has no toxicity to cells, and has a more suitable size and surface for cell growth. Moreover, it has certain transparency, which can directly observe the adhesion, expansion and growth of adherent cells under the microscope.

●The microcarrier is suspended in the medium, providing a uniform growth environment for cells. The culture parameters (such as pH, gas pressure, DO, etc.) are easy to monitor and control online, and the production process is more repeatable.

●Cell harvest process is simple, reduce the waste of human, physical and financial, labor intensity is small, easy to operate, less personnel required, greatly reduce pollution, the process is easy to scale up production.

3.VERO microsphere carrier 3D culture solution

●Commercial culture-medium

VERO SFM01 medium is serum-free medium, free of serum and any animal-derived components and hydrolysates. It is suitable for adherent culture of VERO cells in serum-free culture system, and can be used for large-scale culture and product expression production of VERO cells in 2D(culture bottle, cell factory, etc.) and 3D microcarrier reactor, without adding serum in the culture process. Support VERO rapid and high density amplification and high efficient and stable product expression.It can be used in the research and development and production process of vaccines and other related products, and can support the overall process from research and development to large-scale production.

| Product name | Model/article number | Cell type | Applicable direction |

| VERO SFM01 | LQ25, 1000mL(liquid) | VERO | Biologic drug vaccine production |

| DP25, 50L,100L (dry powder) | VERO | Biologic drug vaccine production |

PDE RecTrypsin is a serine protease capable of selecting peptide chains formed from the carboxyl terminus of lysine or arginine from hydrolyzed proteins to degrade intercellular binding proteins. This product was obtained by gene recombination technology and has no animal-derived components. This product was expressed in recombinant Pichia pastoris and obtained by isolationbitors such as DFP, PMSF and TLCK. It has the same activity and specificity of natural trypsin.It can be used in vaccine, stem cell, drug screening, antibody and other fields of cell digestio and purification.This product is a cell culture-grade recombinant trypsin without enzyme inhin process.

| Product name | Model/article number | Cell type | Applicable direction |

| PDE RecTrypsin-DP01 | PDE-DP01-100/1000 | Versatility | Vaccines, stem cells, drug screening, antibodies, etc |

| PDE RecTrypsin-LQ01 | PDE-LQ01-500 | Versatility | Vaccines, stem cells, drug screening, antibodies, etc |

●Single-use bioreactor --CES-10L

●Disposable Cell culture bag -- 2L

4、CES system applied to VERO microsphere carrier 3D culture method

1.Seed cell resuscitation culture: VERO cells were frozen and resuscitated in 37℃ water bath at 40000cell/cm2After 4-5 days, the cells were observed to have grown to multilayer and could be digested (300,000-350000 cell/cm)2).

2.VREO pass amplification culture: VERO cell digestion, press 40000cell/cm2It was inoculated to the 10-layer cell factory for amplification culture until the amount of cells required for vector culture in the upper bioreactor was reached.

3. Carrier treatment and upper bag preparation

3.1 Prepare the spherical carrier required for the bag at the rate of 3g/L. Hydrate the carrier with 100mL DPBS per gram in the silicified container. Wait for the carrier to absorb water, expand and settle, and stir gently for at least 3 hours.

3.2. Remove the supernatant and readd DPBS at a rate of 50mL per gram of the carrier. After gentle stirring, stand for more than 15min and remove the supernatant. Readd DPBS and sterilize.

3.3. After the carrier is cooled to room temperature, it is pumped into 2L CES-BAG. After the carrier settles, supernatant is discharged through the perfusion membrane. After that, the medium was washed once, and then 100mL medium was inserted into the medium at the ratio of carrier per gram. The Angle was set as 4, the speed was set as 10, the temperature control was on at 36.5℃, and 5%CO was injected into the medium at 100mL air flow2Balanced medium (PH 7.2-7.4).

4 Inoculate the VERO upper bag

4.1. The number of cells inoculated was calculated according to the surface area of the carrier, as 40000cell/cm2The cell suspension digested by the cell factory was inserted into the pre-balanced 2L CES-BAG containing 3g/L microcarriers, and the culture volume was controlled to be 1L.

4.2. CES parameters were set at the temperature of 36.5℃, Angle of 6° and rotation speed of 16rpm, and the operation lasted for 5min, so that the carrier was fully in contact with VERO cell suspension for about 5min;

4.3. CES parameters were set at temperature 36.5℃, Angle 1° and speed 1 RPM, and 2h was run at low Angle speed to provide a stable environment and promote cell adherence.

4.4. Repeat the steps of 4.2~4.3 for 2~3 times to take a sample and observe the cell adherence.

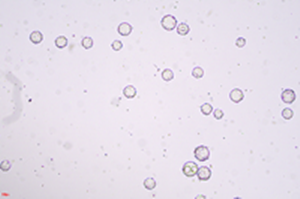

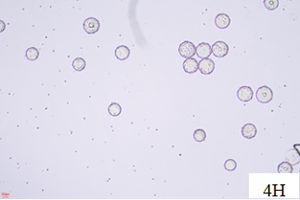

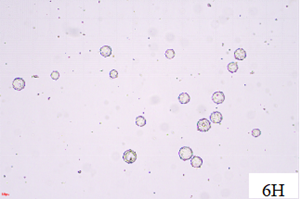

The 2h-4h-6h free VERO cells decreased with the extension of the resting time, and gradually began to stretch by attaching the carrier.

5.VERO cells were amplified and cultured

5.1. Start culture (D0), set and run CES parameters at 37℃, 4°, and 6rpm. Take samples every day for observation and detection of glucose, lactic acid and other contents.

5.2.D2 Increase the rotational speed to 8rpm and continue the culture.

5.3.D3 Start perfusion and perform continuous perfusion culture at 1L/24h.

6.VERO harvest and count

D5 trypsin digest and collect cells, crystal violet stain and count (harvested cells can be scaled up for the next level of culture).

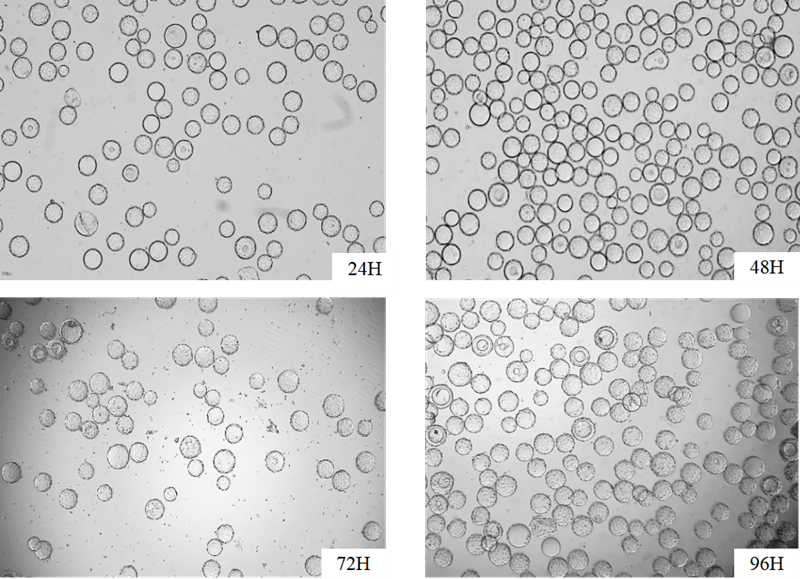

Observation of VERO microsphere carrier culture

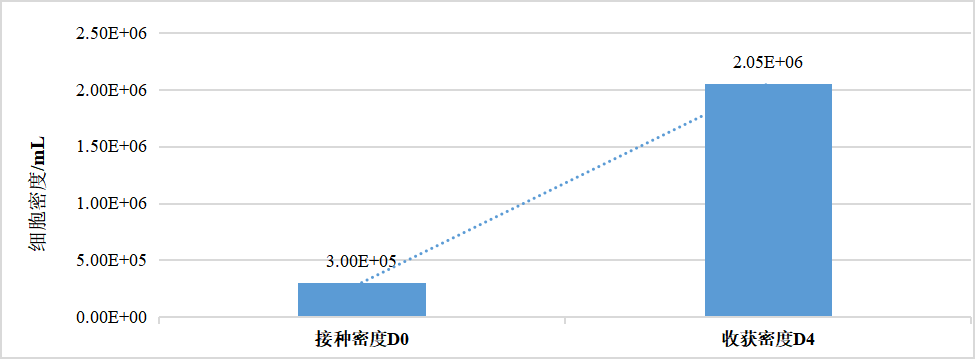

Comparison of TNC before and after VERO microsphere vector culture amplification

ImageAs can be seen from the figure above, VERO was inoculated with 3E5/mL into microsphere carrier for culture. Under the culture system composed of East Fulon CES, CES-BAG and VERO serum-free medium, the cell density reached 2.05E6/mL in D4 days, the cell expansion was 6.83 times, and the average doubling time PDT was 34.625h.

5、The application of CES system in VERO microsphere vector 3D culture method is summarized

The use of Tofflon CES disposable cell amplification system, the closed culture system composed of VERO cell serum-free medium and disposable cell culture bag, can effectively realize the 3D scale-up culture of VERO cell microcarrier, which can be used for VERO scale-up and product expression and production. It can provide an effective solution for the large-scale production of VERO cell-based biological drugs.

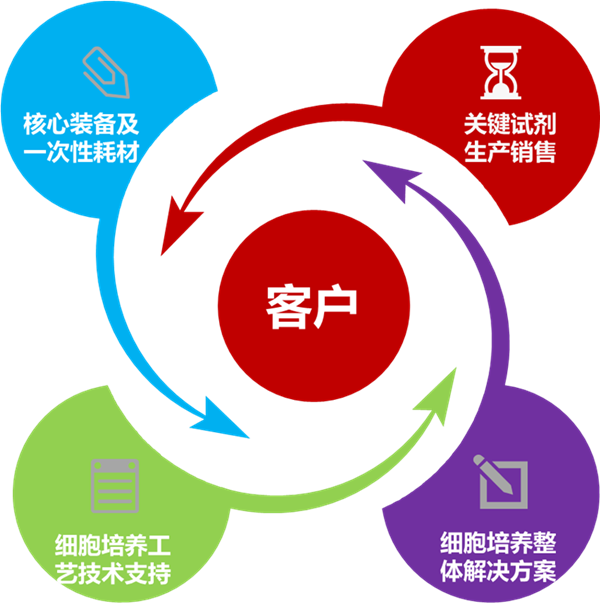

Tofflon Systematizes holistic solutions

We can provide you with:

√Key reagents research and development innovation, application transformation and production

√To provide medium series related products for the field of macromolecular medicine

√It provides serum-free medium for cell and gene therapy, preservation solution for cryopreservation and other key reagents

√Development and support of cell culture technology

√TofflonTofflon core equipment and disposable biological consumables

Please apply for a trial by following the application process below

Scan the above QR code and fill out the form

Our technical experts and sales team will contact you as soon as possible.

Get a free trial of the cell preservation solution!